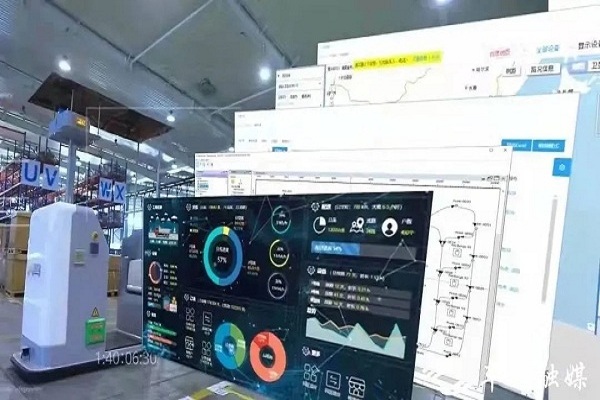

The digital supply chain platform developed by Meritar [Photo provided to en.blycjd.com]

Hubei Meritar Supply Chain Co, based in the Wuhan Economic & Technological Development Zone (WEDZ), is a mature digital supply chain management and smart logistics service provider. According to Deng Xiaohuai, vice general manager of the company, more than half of automobile spare part manufacturers included in the Fortune 500 Company list are Meritar's clients.

The firm registered 100 million yuan ($15.65 million) in sales revenue during the first quarter of this year, up 50 percent over the same period last year.

The digital supply chain platform independently developed by Meritar offers supply chain management and smart logistics services for automakers and other manufacturers. Headquartered in Wuhan, the firm has established 19 branches and 95 outlets around China, covering the nation’s major auto-making bases. It also made the 2021 list of Hubei industrial internet platforms released by the Department of Economy and Information Technology of Hubei Province.

In addition to providing logistical solutions for Hitachi Astemo, ZF, Magna, and Honeywell, the firm also serves the main engine plants of Geely, Ford and Volvo.

"We have rendered our logistical management services in Geely's 13 factories, and our digital supply chain system that runs through the whole industrial process has decreased Geely's transportation costs by 20 percent," said Deng.

When asked why they chose Wuhan for the firm's headquarters, Deng highlighted the city's strong automobile manufacturing foundation, good location, recent performance in the auto industry and talent reserves.